Forklift battery chargers play a crucial role in guaranteeing top performance and extending the lifespan of ROYPOW lithium batteries. Therefore, this blog will guide you through everything you need to know about forklift battery chargers for ROYPOW batteries to make the most out of the batteries.

Charge with ROYPOW Original Forklift Battery Chargers

Features of ROYPOW Forklift Battery Chargers

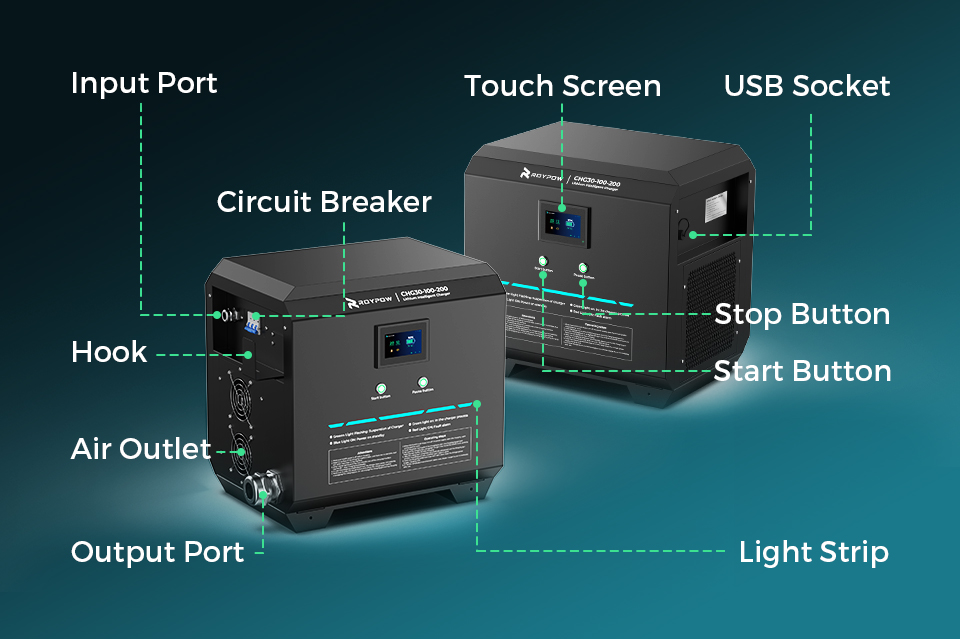

ROYPOW has specially designed the chargers for the forklift battery solutions. These forklift battery chargers feature multiple safety mechanisms, including over/under voltage, short circuit, Anti-reverse connection, phase loss, and current leakage protection. Moreover, ROYPOW chargers can communicate in real time with the Battery Management System (BMS) to ensure battery safety and improve charging efficiency. During the charging process, power to the forklift is disconnected to prevent drive-off.

How to Use ROYPOW Forklift Battery Chargers

When the battery level drops below 10%, it will alert to prompt charging, and it’s time to drive to the charging area, switch off, and open the charging cabin and protective cover. Before charging, check the charger cables, charging sockets, charger casing, and other equipment to make sure they are in proper working condition. Look for signs of water and dust ingress, burning, damage, or cracks, and if not, you can go for charging.

First, detach the charging gun. Connect the charger to the power supply and the battery to the charger. Next, press the start button. Once the system is free of faults, the charger will start charging, accompanied by the illumination of the display and indicator light. The display screen will provide real-time charging information such as current charging voltage, charging current, and charging capacity, while the indicator light strip will display the charging status. A green light signals that the charging process is underway, while a flashing green light indicates a pause in the forklift battery charger. A blue light signifies standby mode, and a red light indicates a fault alarm.

Unlike lead-acid forklift batteries, charging the ROYPOW lithium-ion battery from 0 to 100% only takes a few hours. Once fully charged, pull out the charging gun, secure the charging protection cover, close the hatch door, and disconnect the charger power supply. Since the ROYPOW battery can be opportunity charged without compromising its cycle life — allowing for short charging sessions during any break in the shift schedule — you can charge it for a while, press the stop/pause button, and unplug the charging gun to operate for another shift.

In case of an emergency during charging, it needs to press the stop/pause button immediately. Doing otherwise could cause dangerous situations where electricity arcs between the battery and the charger cables.

Charge ROYPOW Batteries with Non-Original Forklift Battery Chargers

ROYPOW matches each lithium-ion battery with a forklift battery charger for an ideal pairing. It’s recommended to use these batteries bundled with their corresponding chargers. This will help protect your warranty and ensure simpler and more effective technical support should you need it. However, if you want to use other brands of chargers to complete the charging tasks, there are a few factors you should consider before deciding on what type of forklift charging charger:

√ Match to ROYPOW lithium battery’s specifications

√ Consider the charging speed

√ Check the charger’s efficiency rating

√ Evaluate the battery charger’s technologies and functions

√ Understand the details of forklift battery connectors

√ Measure the physical space for charging devices: wall-mounted or stand-alone

√ Compare the costs, product lifespan, and warranty of different brands

√ …

Considering all these factors, you’re making such a decision that will ensure smooth forklift operation, promote battery longevity, minimize the frequency of battery replacement, and contribute operation cost savings over time.

Common Faults & Solutions of Forklift Battery Chargers

While ROYPOW forklift battery chargers boast robust construction and design, it’s crucial to know common faults and solutions for effective maintenance. Here are a few as follows:

1.Not Charging

Check the display panel for error messages and inspect whether the charger is properly connected and the charging environment is suitable or not.

2.Not Charging to Full Capacity

Assess the battery’s condition, as old or damaged batteries may not charge fully. Verify that the charger settings align with the battery specifications.

3.Charger not Recognizing the Battery

Check if the control screen is showing that it’s CAN connected.

4.Display Errors

Check the charger’s user manual for troubleshooting guidance related to specific error codes. Ensure proper connection of the charger to both the forklift battery and power source.

5.Abnormally Shorter Charger Life

Ensure the charger is serviced and maintained correctly. Misuse or neglect could reduce its lifespan.

When the fault still exists, it’s recommended to consult with a professional or staff with specialized training to prevent more significant problems that could lead to costly maintenance or replacements, and possibly safety hazards to forklift operators.

Tips for Proper Handling and Care for Forklift Battery Chargers

To ensure the longevity and efficiency of your ROYPOW forklift battery charger or any other brand, here are some essential safety tips for handling and maintenance:

1.Follow Correct Charging Practices

Always follow the instructions and steps given by the manufacturers. Wrong connections could result in arcing, overheating, or electrical shorts. Remember to keep open flames and sparks away from the charging area to avoid fire potential.

2.No Extreme Working Conditions for Charging

Exposing your forklift battery chargers to extreme environmental conditions such as excessive heat and cold could affect their performance and lifespan. Optimum ROYPOW forklift battery charger performance is typically achieved between -20°C and 40°C.

3.Regular Inspection and Cleaning

Regular inspection of chargers is recommended to detect minor issues like loose connections or damaged cables. As dirt, dust, and grime buildup can increase the risk of electrical shorts and potential issues. clean the chargers, connectors, and cables regularly.

4.Operated by Trained Operators

It’s crucial to have charging, inspections, maintenance, and repairs carried out by a well-trained and experienced professional. Improper handling due to lack of proper training or instructions could lead to charger damage and potential hazards.

5.Software Upgrades

Updating the charger software helps optimize the charger’s performance for current conditions and enhances its efficiency.

6.Proper and Safe Storage

When storing the ROYPOW forklift battery charger for extended periods, place it in its box at least 20cm above ground and 50cm away from walls, heat sources, and vents. Warehouse temperature should range from -40℃ to 70℃, with normal temperatures between -20℃ and 50℃, and relative humidity between 5% and 95%. The charger can be stored for two years; beyond that, re-testing is necessary. Power on the charger every three months for at least 0.5 hours.

Handling and care are not a one-time task; it’s a continuous commitment. By performing proper practices, your forklift battery charger can reliably serve your business for many years to come.

Conclusion

To conclude, a forklift battery charger is an integral part of modern warehousing. Knowing more about the ROYPOW chargers, you can enhance the material handling efficiency of your forklift fleet operations, thereby maximizing the return on your battery charger investment.