The cost of a forklift battery varies wildly depending on the type of battery. For a lead-acid forklift battery, the cost is $2000-$6000. When using a lithium forklift battery, the cost is $17,000-$20,000 per battery. However, while the prices may vary wildly, they do not represent the actual cost of owning either type of battery.

The True Cost of Purchasing Lead-Acid Forklift Batteries

Determining the actual forklift battery cost requires understanding various aspects of the different types of batteries. A wise manager will carefully examine the underlying cost of owning either type before deciding. Here is the actual cost of a forklift battery.

Time Forklift Battery Cost

In any warehouse operation, the significant cost is labor, measured in time. When you purchase a lead acid battery, you significantly increase the actual forklift battery cost. Lead-acid batteries require tons of man-hours per year per battery to ensure they operate correctly.

Additionally, each battery can only be used for around 8 hours. It must then be placed in a special storage area to charge and cool down for 16 hours. A warehouse that operates 24/7 would mean at least three lead-acid batteries per forklift daily to ensure 24-hour operation. Additionally, they would have to purchase extra batteries when some needed to be taken offline for maintenance.

That means more paperwork and a dedicated team to keep track of the charging, changes, and maintenance.

Storage Forklift Battery Cost

Lead acid batteries used in forklifts are massive. Consequently, the warehouse manager must sacrifice some storage space to accommodate the numerous lead-acid batteries. Additionally, the warehouse manager has to modify the storage space where the lead-acid batteries will be placed.

According to guidelines by the Canadian Center for Occupational Health and Safety, lead-acid battery charging areas must meet an extensive list of requirements. All of these requirements incur additional costs. It also requires specialized equipment to monitor and secure the lead acid batteries.

Occupational Risk

Another cost is the occupational risk associated with lead-acid batteries. These batteries contain liquids that are highly corrosive and airborne. If one of these massive batteries spills its content, the warehouse must shut down operations as the spill is cleaned. That would incur an additional time cost for the warehouse.

Replacement Cost

The initial lead-acid forklift battery cost is relatively low. However, these batteries can only handle up to 1500 cycles if adequately maintained. It means that every 2-3 years, the warehouse manager will have to order a fresh batch of these massive batteries. Also, they will have to incur an extra cost to dispose of the used batteries.

The True Cost of Lithium Batteries

We have examined the actual forklift battery cost of lead-acid batteries. Here is a summary of how much it costs to use lithium batteries in the forklift.

Space Saving

One of the most significant advantages for a warehouse manager when using lithium batteries is the space they save. Unlike lead-acid, lithium batteries do not need special modifications to the storage space. They are also light and more compact, which means they occupy significantly less space.

Time Savings

One of the significant benefits of lithium batteries is the fast charging. When paired with the correct charger, a lithium charge can reach full capacity in about two hours. That comes with the benefit of opportunity-charging, which means workers can charge them during breaks.

Since the batteries do not have to be removed for charging, you do not require a separate crew to handle the charging and swapping of these batteries. Lithium batteries can be charged during 30-minute breaks by workers throughout the day, ensuring that the forklifts operate 24 hours a day.

Energy Savings

A hidden forklift battery cost when using lead-acid batteries is energy wastage. A standard lead-acid battery is only around 75% efficient. It means you lose around 25% of all power purchased to charge the batteries.

In comparison, a lithium battery can be up to 99% efficient. It means that when you switch from lead-acid to lithium, you will immediately notice a double-digit reduction in your energy bill. Over time, those costs can add up, ensuring that it will cost less to own lithium batteries.

Better Worker Safety

According to OSHA data, most lead-acid battery accidents occur during swaps or watering. By eliminating them, you eliminate a significant hazard from the warehouse. These batteries contain sulfuric acid, where even a tiny spill can lead to significant incidents at the workplace.

The batteries also carry an inherent risk of explosion. This is especially so if the charging area is not adequately ventilated. OSHA rules require that warehouses install hydrogen sensors and take various other measures to ensure the safety of workers.

Better Performance in Cold Warehouses

If you operate in a cold or freezing warehouse, the actual forklift battery cost of using lead-acid batteries will become immediately apparent. Lead-acid batteries can lose up to 35% of their capacity at temperatures near freezing point. The result is that battery changes become more frequent. Additionally, it means you require more energy to charge the batteries. With a lithium forklift battery, cold temperatures do not significantly impact performance. As such, you will save time and money on energy bills by using lithium batteries.

Improved Productivity

In the long run, installing lithium batteries will reduce the downtime for forklift operators. They no longer have to make detours to swap out batteries. Instead, they can focus on the core mission of the warehouse, which is to move goods from one point to another efficiently.

Improving the Competitiveness of Operations

One of the many benefits of installing lithium batteries is that it improves a company’s competitiveness. While a company must keep short-term costs down, managers must also consider long-term competitiveness.

If it takes them twice as long to process goods at their warehouse, they will eventually lose out to the competition based on speed alone. In the highly competitive business world, short-term costs must always be weighed against long-term viability. In this scenario, failing to make the necessary upgrades now would mean they lose a significant portion of their potential market share.

Can Existing Forklifts Be Retrofitted With Lithium Batteries?

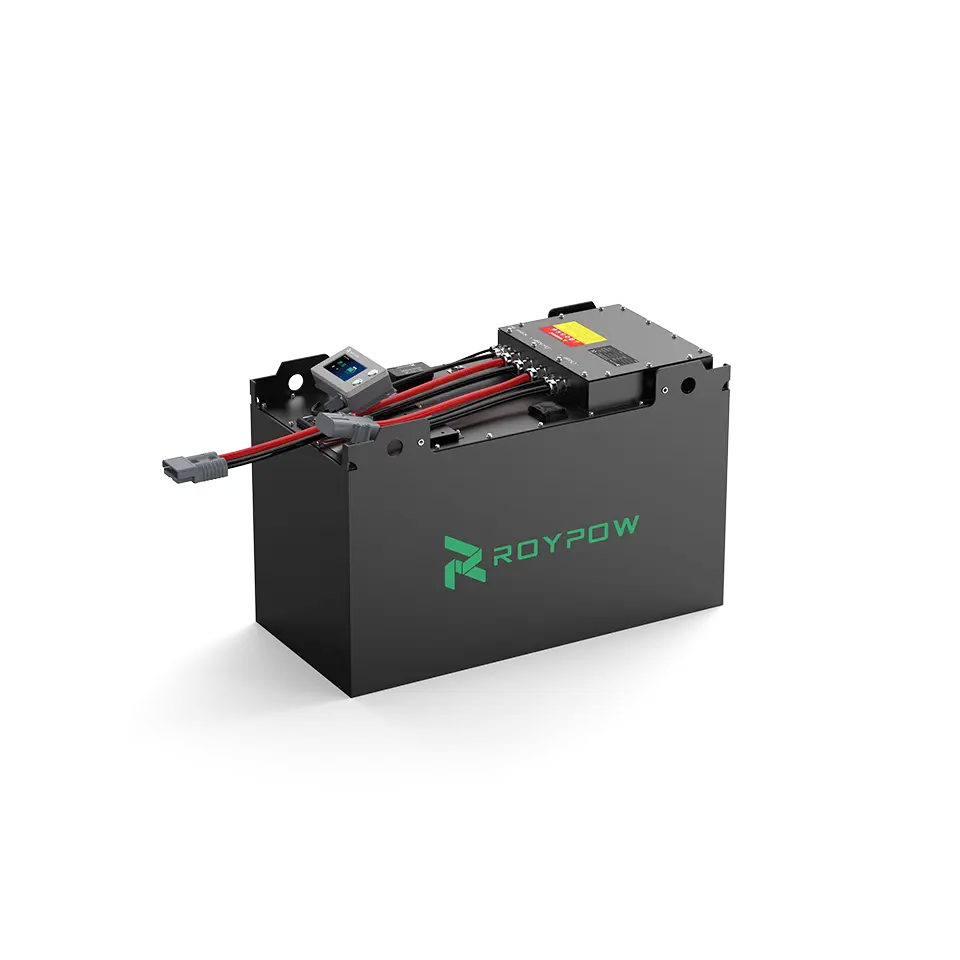

Yes. For instance, ROYPOW offers a line of LiFePO4 Forklift Batteries that can be easily connected to an existing forklift. These batteries can handle up to 3500 charging cycles and have a 10-year lifespan, with a 5-year warranty. They are fitted with a top-of-the-line battery management system designed to ensure the optimal operation of the battery throughout its life.

Lithium is the Smart Choice

As a warehouse manager, going lithium could be the wisest investment in the long-term future of an operation you ever make. It is an investment in reducing the overall forklift battery cost by looking closely at the actual cost of each type of battery. Within the lifespan of the battery, users of lithium batteries will recoup their entire investment. The in-built technologies of lithium technology are too great of an advantage to pass up.

Related article:

Why choose RoyPow LiFePO4 batteries for material handling equipment

Lithium ion forklift battery vs lead acid, which one is better?

Are Lithium Phosphate Batteries Better Than Ternary Lithium Batteries?