Cold storage or refrigerated warehouses are widely used to protect perishable products like pharmaceuticals, food and beverage items, and raw materials during transport and storage. While these cold environments are crucial for preserving product quality, they can also challenge forklift batteries and overall performance.

Challenges for Batteries in the Cold: Lead Acid or Lithium?

In general, batteries discharge faster at low temperatures, and the lower the temperature, the lower the battery capacity. Lead-acid forklift batteries degrade quickly when operating in colder temperatures, both in their performance and lifespan. They may experience the available capacity drops by up to 30 to 50 percent. Since the lead-acid battery absorbs the energy poorly in coolers and freezers, charging time will extend. Therefore, two replaceable batteries, i.e. three lead-acid batteries per device, are usually required. This increases the replacement frequency, and ultimately, the fleet performance decreases.

For cold storage warehouses that face unique operating challenges, lithium-ion forklift battery solutions address many of the problems associated with lead-acid batteries.

- Lose little or no capacity in a cold environment due to lithium technology.

- Charge to full quickly and support opportunity charging; increased equipment availability.

- Using a Li-ion battery in a cold environment does not shorten its usable life.

- No need to replace heavy batteries, no need for replacement batteries or a battery room.

- Little or no voltage drop; fast lifting and travel speeds at all levels of discharge.

- 100% clean energy; no acid fumes or spills; no gassing during charging or operation.

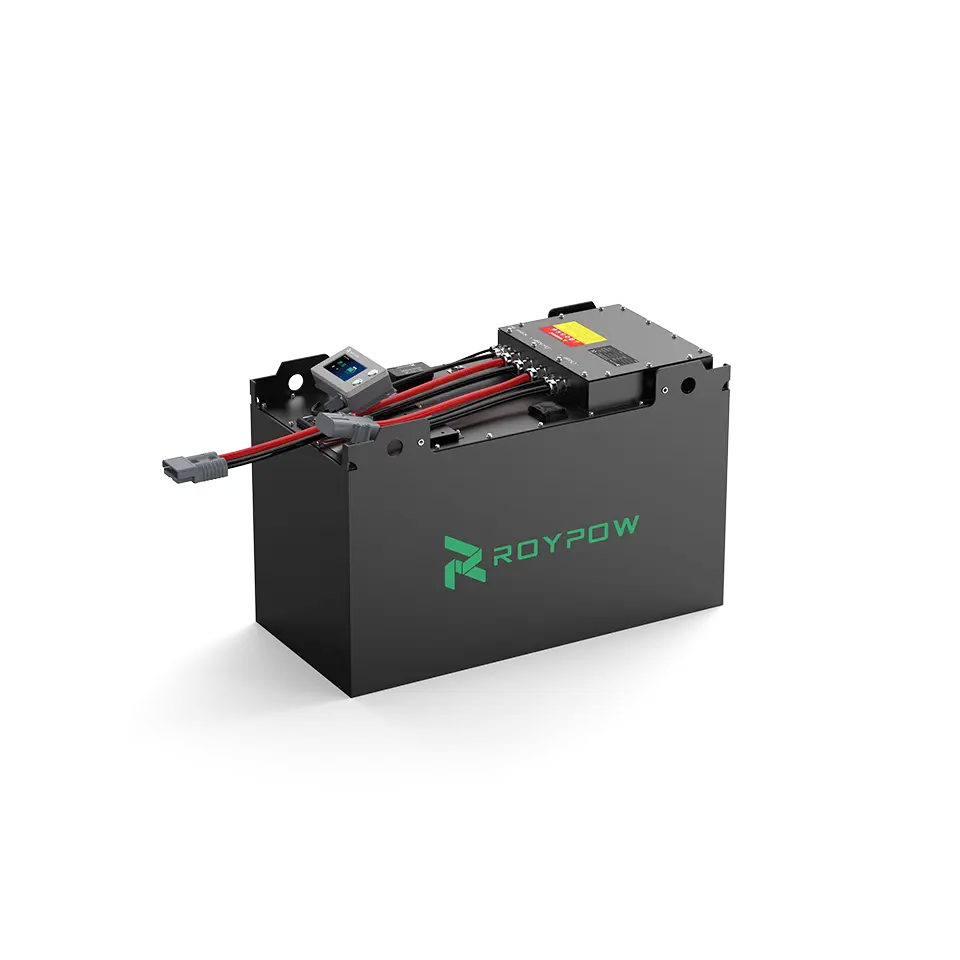

ROYPOW’s Lithium Forklift Battery Solutions for Cold Environments

ROYPOW’s specialized lithium forklift battery solutions are up to the challenges of material handling in cold storage warehouses. Advanced Li-ion cell technologies and a robust internal and external structure ensure peak performance in low temperatures. Here are some of the product highlights:

Highlight 1: On-Board Thermal Insulation Design

To keep optimal temperatures and avoid thermal runaway when using or charging, each anti-freeze forklift battery module is fully covered with thermal insulation cotton, the high-quality Gray PE insulation cotton. With this protective cover and heat generated during operation, ROYPOW batteries maintain performance and safety standards even in temperatures as low as -40 degrees Celsius by preventing rapid cooling.

Highlight 2: Pre-Heating Function

Moreover, ROYPOW forklift batteries feature a pre-heating function. There is a PTC heating plate at the bottom of the forklift battery module. When the module temperature drops below 5 degrees Celsius, the PTC element activates and heats the module until the temperature reaches 25 degrees Celsius for optimal charging. This ensures the module can discharge at a normal rate at a low temperature.

Highlight 3: IP67 Ingress Protection

The charging and discharging plugs of ROYPOW forklift battery systems are equipped with reinforced waterproof cable glands with built-in sealing rings. Compared with standard forklift battery cable connectors, they provide enhanced protection against external dust and moisture ingress and ensure reliable power transfer. With strict air tightness and waterproofness testing, ROYPOW offers an IP rating of IP67, the gold standard for electric forklift batteries for refrigerated storage handling applications. You won’t need to worry that external water vapor could compromise its integrity.

Highlight 4: Internal Anti-Condensation Design

Unique silica gel desiccants are placed inside the forklift battery box to address internal water condensation that may occur when operating in cold storage environments. These desiccants efficiently absorb any moisture, ensuring the internal battery box remains dry and functioning optimally.

Performance Test in Cold Environments

To guarantee the battery performance in low-temperature environments, ROYPOW laboratory has conducted a minus 30 degrees Celsius low discharge testing. With a low temperature of 0.5C discharging rate, the battery discharges from 100% to 0%. Until the battery energy is empty, the discharge time is about two hours. The results showed that the anti-freeze forklift battery lasted nearly the same as under room temperature. During the discharge process, the internal water condensation was also tested. Through the internal monitoring by being photographed every 15 minutes, there was no condensation inside the battery box.

More Features

In addition to the specialized designs for cold storage conditions, ROYPOW IP67 anti-freeze lithium forklift battery solutions boast most of the robust features of standard forklift batteries. Built-in intelligent Battery Management System (BMS) ensures the forklift battery system’s peak performance and safety through real-time monitoring and multiple safe protections. This not only maximizes efficiency but also extends the battery life.

With up to 90% usable energy and the ability for fast charging and opportunity charging, downtime is significantly reduced. Forklift operators can recharge the battery during breaks, allowing one battery to last through two to three operation shifts. What’s more, these batteries are built to automotive-grade standards with a design life of up to 10 years, guaranteeing durability even in the harshest conditions. This means fewer replacement or maintenance requirements and reduced maintenance labor costs, ultimately lowering the total cost of ownership.

Conclusion

To conclude, ROYPOW lithium batteries equipped in electric forklifts are a good match for cold storage operations, ensuring no drop in performance for your intralogistics processes. By seamlessly integrating into the workflow, they empower operators to accomplish tasks with greater ease and speed, ultimately driving productivity gains for the business.

Related article:

What you should know before buying one forklift battery?

Lithium ion forklift battery vs lead acid, which one is better?

5 Essential Features of ROYPOW LiFePO4 Forklift Batteries