What is the best battery for a forklift? When it comes to electric forklift batteries, there are a number of options to choose from. Two of the most common types are lithium and lead acid batteries, both of which have their own benefits and drawbacks.

Despite the fact that lithium batteries are becoming increasingly popular, lead acid batteries remain the most commonly used option in forklifts. This is largely due to their low cost and broad availability. On the other hand, Lithium-Ion (Li-Ion) batteries have their own advantages such as lighter weight, faster charging time and longer life span when compared to traditional lead acid batteries.

So are lithium forklift batteries better than lead acid? In this article, we will discuss the pros and cons of each kind in detail to help you make an informed decision which one is best suited for your application.

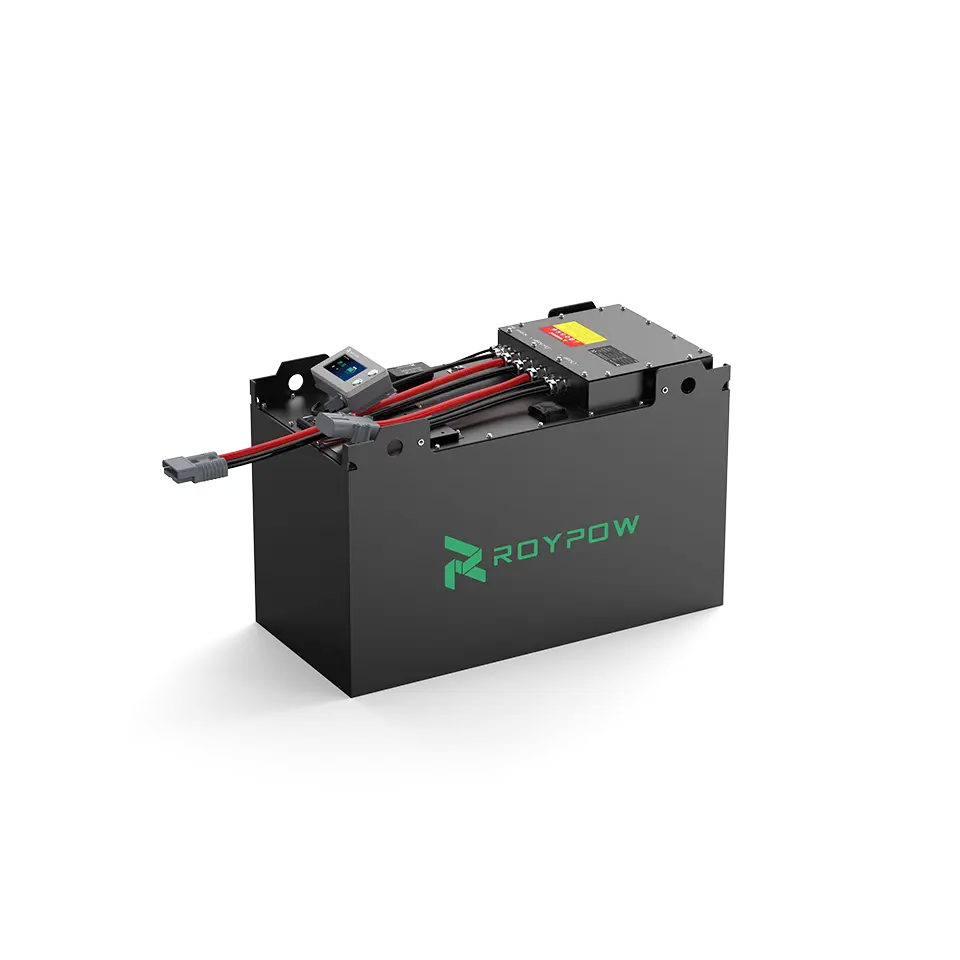

Lithium-ion battery in forklifts

Lithium-ion batteries are becoming increasingly popular for use in material handling equipment, and for good reason. Lithium-ion batteries have a longer lifespan than lead acid batteries and can be charged more quickly – typically in 2 hour or less. They also weigh significantly less than their lead acid counterparts, which makes them much easier to handle and store on your forklifts.

In addition, Li-Ion batteries require far less maintenance than lead acid ones, freeing up more time to focus on other aspects of your business. All of these factors make lithium-ion batteries a great choice for anyone looking to upgrade their forklift’s power source.

Lead acid forklift battery

Lead acid forklift batteries are the most commonly used type of battery in forklifts due to their low cost of entry. However, they have a shorter lifespan than lithium-ion batteries and take several hours or more to charge. Additionally, lead acid batteries are heavier than Li-Ion ones, making them more difficult to handle and store on your forklifts.

Here is a comparison table between Lithium ion forklift battery vs lead acid:

|

Specification |

Lithium-Ion Battery |

Lead Acid Battery |

|

Battery life |

3500 cycles |

500 cycles |

|

Battery charge Time |

2 hours |

8-10 hours |

|

Maintenance |

No maintenance |

High |

|

Weight |

Lighter |

Heavier |

|

Cost |

Upfront cost is higher, lower cost in the long run |

Lower entry cost, higher cost in the long run |

|

Efficiency |

Higher |

Lower |

|

Environmental Impact |

Green-friendly |

Contain sulfuric acid, toxic substances

|

Longer lifespan

Lead acid batteries are the most commonly chosen option due to their affordability, but they only offer up to 500 cycles of service life, which means they need to be replaced every 2-3 years. Alternatively, lithium ion batteries provide a much longer service life of about 3500 cycles with proper care, meaning they can last up to 10 years.

The clear advantage in terms of service life goes to lithium ion batteries, even if their higher initial investment might be daunting for some budgets. That said, although investing up front for lithium ion battery packs may be a financial strain initially, over time this translates into spending less money on replacements due to the extended lifespan that these batteries offer.

Charging

Charging process of forklift batteries is critical and complex. Lead acid batteries require 8 hours or more to charge fully. These batteries must be charged in a designated battery room, usually outside the main workplace and away from the forklifts due to the heavy lifting involved with moving them.

While lithium-ion batteries can be charged in considerably less time – often as fast as 2 hours. Opportunity charging, which allows batteries to be recharged while they are in the forklifts. You can charge the battery during shifts, lunches, break times.

In addition, lead acid batteries require a cool-down period after charging, which adds another layer of complexity to managing their charging times. This often requires workers to be available for longer periods of time, especially if charging is not automated.

Therefore, companies must ensure that they have adequate resources available to manage the charging of forklift batteries. Doing so will help to keep their operations running smoothly and efficiently.

Lithium-ion forklift battery cost

When compared to lead acid batteries, Lithium-Ion forklift batteries have a higher upfront cost. However, it’s important to keep in mind that Li-Ion batteries offer a number of advantages over lead acid ones.

Firstly, Lithium-ion batteries are highly efficient when charging and use less energy than lead-acid alternatives, resulting in lower energy bills. Furthermore, they can provide increased operational shifts without requiring battery swaps or reloads, which can be costly procedures when using traditional lead-acid batteries.

Regarding maintenance, lithium-ion batteries do not need to be serviced in the same way as their lead-acid counterparts, meaning less time and labor is spent cleaning and maintaining them, ultimately reducing maintenance costs over their lifetime. This is why more and more businesses are taking advantage of these long-lasting, reliable, and cost-saving batteries for their forklift needs.

For RoyPow lithium forklift battery, the design lifespan is 10 years. We calculate that you can save about 70% overall by converting from lead-acid to lithium in 5 years.

Maintenance

One of the main disadvantages of lead-acid forklift batteries is the high maintenance required. These batteries need regular watering and equalization to ensure they operate at peak performance, and the acid spills during maintenance can be hazardous to workers and equipment.

In addition, lead acid batteries tend to degrade more quickly than lithium-ion batteries due to their chemical composition, meaning they require more frequent replacement. This can result in higher long-term costs for businesses that rely heavily on forklifts.

You should add distilled water to a lead-acid forklift battery after it has been fully charged and only when the fluid level is below the recommendation. The frequency of adding water depends on the usage and charging patterns of the battery, but it is typically recommended to check and add water every 5 to 10 charging cycles.

In addition to adding water, it’s important to regularly inspect the battery for any signs of damage or wear and tear. This can include checking for cracks, leaks, or corrosion on the battery terminals. You also need to change battery during shifts, as lead acid batteries tend to discharge quickly, in terms of multi-shift operations, you may need 2-3 lead-acid batteries for 1 forklift, demanding additional storage space.

On the other hand, lithium forklift battery requires no maintenance , no need to add water because the electrolyte is solid-state, and no need to check for corrosion, because the batteries are sealed and protected. It does not require extra batteries to change during single-shift operation or multi-shifts, 1 lithium battery for 1 forklift.

Safety

The risks to workers when maintaining lead acid batteries is a serious concern that must be addressed properly. One potential hazard is the inhalation of harmful gases from charging and discharging the batteries, which can be fatal if proper safety measures are not taken.

Additionally, acid splash due to imbalance in chemical reaction during battery maintenance poses another risk to workers where they might inhale chemical fumes or even get physical contact with corrosive acids.

Furthermore, exchanging new batteries during shifts can be dangerous due to the heavy weight of lead-acid batteries, which can weigh hundreds or thousands of pounds and pose a risk of falling or hitting workers.

In comparison to lead-acid batteries, lithium ion batteries are much safer for workers as it does not emit dangerous fumes nor contain any sulfuric acid that can spill out. This significantly reduces the potential health risks associated with battery handling and maintenance, giving peace of mind for both employers and employees.

Lithium battery requires no exchange during shifts, it has battery management system(BMS) that can protect the battery from overcharging, over discharging, overheat, etc. RoyPow lithium forklift batteries can be used at temperatures ranging from -20℃ to 55℃.

Although lithium-ion batteries are generally less dangerous than their predecessors, it is still essential to provide proper protective gear and training to ensure good working practices and prevent any unnecessary incidents.

Efficiency

Lead acid batteries experience a constant decrease in voltage during their discharge cycle, which can significantly impact the overall energy efficiency. Not only that, but such batteries also remain constantly bleeding energy even if the forklift is idle or charging.

In comparison, lithium-ion battery technology has proven to deliver superior efficiency and power savings compared with lead acid via its constant voltage level throughout the entire discharge cycle.

Additionally, these more modern Li-Ion batteries are more powerful, being capable of storing about three times more power than their lead acid counterparts. The self-discharging rate of lithium forklift battery is less than 3% per month. Altogether, it’s clear that when it comes to maximizing energy efficient and output for operation of a forklift, Li-Ion is the way to go.

Major equipment manufacturers recommend charging lead-acid batteries when their battery level remains between 30% to 50%. On the other hand, lithium-ion batteries can be charged when their state of charge (SOC) is between 10% to 20%. The depth of discharge (DOC) of lithium batteries is superior compared to lead-acid ones.

In conclusion

When it comes to initial cost, lithium-ion technology tends to be pricier than traditional lead acid batteries. However, in the long run, lithium-ion batteries can save you money due to their superior efficiency and power output.

Lithium-ion batteries provide many advantages over lead acid batteries when it comes to forklift use. They require less maintenance and do not emit toxic fumes or contain hazardous acids, making them safer for workers.

Lithium-ion batteries also offer more energy-efficient output with consistent power throughout the entire discharge cycle. They are capable of storing three times more power than lead acid batteries. With all of these benefits, it is no wonder why lithium-ion batteries are becoming increasingly popular in the material handling industry.

Related article:

Why choose RoyPow LiFePO4 batteries for material handling equipment

Are Lithium Phosphate Batteries Better Than Ternary Lithium Batteries?