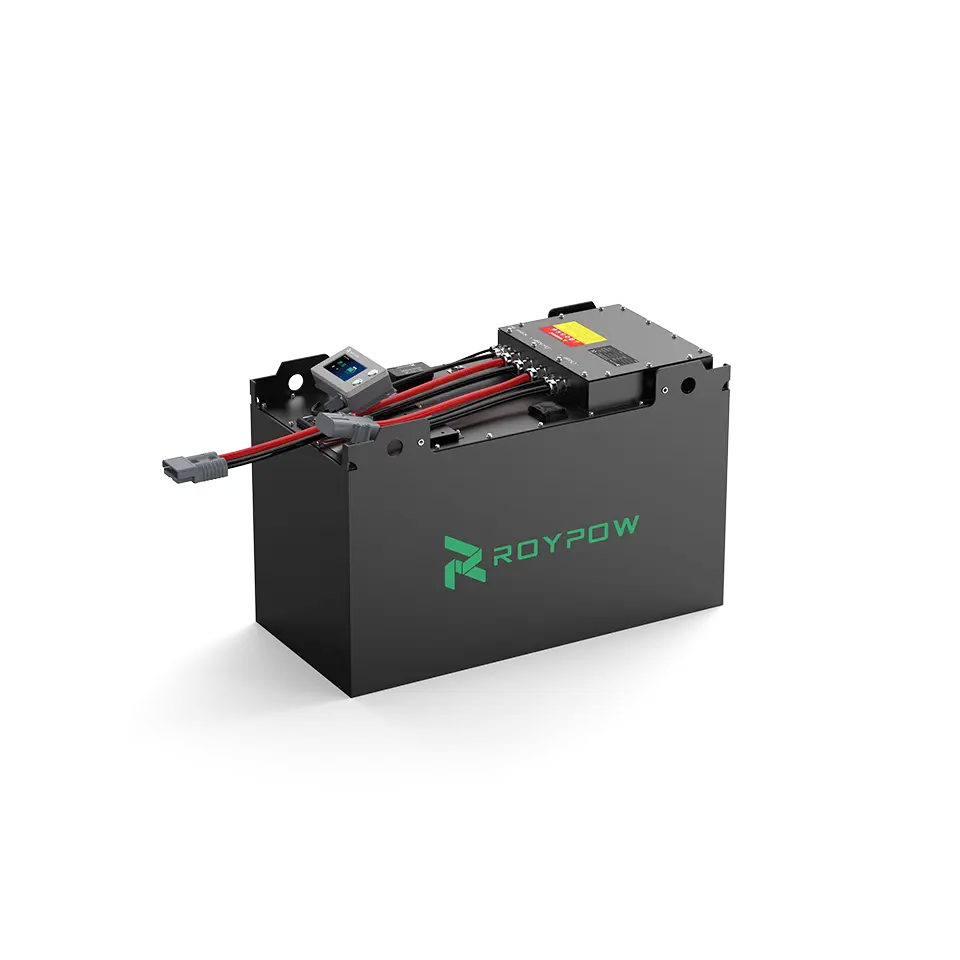

In the evolving electric forklift battery market, ROYPOW has become the market leader with industry-leading LiFePO4 solutions for material handling. ROYPOW LiFePO4 forklift batteries have much to favor from clients worldwide, including efficient performance, unrivaled safety, uncompromising quality, complete solution packages, and lower total cost of ownership. This blog will guide you through 5 essential features of ROYPOW LiFePO4 forklift batteries to see how these features make a difference to the forklift battery performance and contribute to solidifying ROYPOW’s position in the market.

Fire Extinguishing System

The first feature of ROYPOW material handling batteries is the unique hot aerosol forklift fire extinguishers that set ROYPOW apart from its competitors and redefine the protection of thermal runaways. Utilizing the LiFePO4 chemistry, considered the safest chemistry among lithium-ion types, ROYPOW forklift batteries ensure a lower risk of overheating and catching fire due to their enhanced thermal and chemical stability. To prevent unexpected fires, ROYPOW has engineered efficient forklift fire extinguishers for fire safety.

Each battery unit is equipped with one or two forklift fire extinguishers inside, with the former intended for smaller voltage systems and the latter for larger ones. In case of fire, the extinguisher is triggered automatically upon receiving an electric starting signal or detecting an open flame. A thermal wire ignites, releasing an aerosol-generating agent. This agent decomposes into a chemical coolant for swift and effective firefighting.

In addition to forklift fire extinguishers, ROYPOW electric forklift batteries incorporate multiple protective designs to further mitigate the risk of thermal runaway. Internal modules feature fire-resistant materials. For instance, all modules must have insulation protection foam. The inbuilt, self-developed Battery Management System (BMS) offers intelligent protection against short circuits, overcharge/over-discharge, overcurrent, over-temperature, and other potential hazards. The batteries are strictly manufactured and tested, passing safety certifications such as UL 9540A, UN 38.3, UL 1642, UL2580, etc.

Smart 4G Module

The second key feature of ROYPOW LiFePO4 batteries for electric forklifts is the 4G module. Each forklift battery comes equipped with a specially designed 4G module. It has a compact design rated at IP65 and supports easy plug-and-play. The cloud-based card system eliminates the need for a physical SIM card. With network connectivity spanning over 60 countries, once successfully logged in, the 4G module enables remote monitoring, diagnosing, and software upgrades via the web page or phone interface.

Real-time monitoring allows electric forklift operators to check the battery voltage, current, capacity, temperature, and more and analyze the operation data, thus ensuring optimal battery status and performance. In case of faults, operators will receive immediate alarms. When unable to solve the issues, the 4G module provides remote online diagnosis to get everything right and prepare the forklifts for the following shifts as soon as possible. With OTA (over-the-air) connectivity, operators can upgrade the battery software remotely, ensuring the battery system always benefits from the latest features and optimized performance.

ROYPOW 4G module also features GPS positioning to help track and locate the forklift. The customizable remote forklift battery locking function has been tested and proven effective in many cases, particularly benefiting forklift rental businesses by facilitating fleet management and maximizing profitability.

Low-Temperature Heating

Another outstanding feature of ROYPOW forklift batteries is their low-temperature heating capability. During cold seasons or when operating in cold storage environments, lithium batteries may experience slower charging and reduced power capacity, resulting in performance degradation. To address these challenges, ROYPOW has developed a low-temperature heating function.

Typically, ROYPOW heated forklift batteries can operate normally at temperatures as low as -25℃, with specialized cold storage batteries capable of withstanding ultra-cold temperatures down to -30℃. ROYPOW laboratory has tested the working time by subjecting the battery under -30℃ conditions, with a 0.2 C discharging rate following a full charge cycle from 0% to 100%. The results showed that the heated forklift batteries lasted nearly the same as under room temperature. This increases the service life of the batteries and minimizes the need for additional battery purchases or maintenance expenses.

For operations in regions with hot climates, the standard low-temperature heating function can be removed. Additionally, to avoid water condensation in cold environments, all ROYPOW heated forklift batteries feature robust sealing mechanisms. The batteries for cold storage applications have even achieved an IP67 water and dust ingress protection rating with specially designed internal structures and plugs.

NTC Thermistor

Following next is the feature of NTC (Negative Temperature Coefficient) thermistors integrated into ROYPOW Lithium iron phosphate batteries for forklifts, serving as an ideal partner for the BMS to perform intelligent protections. Since the battery may cause the temperature to be too high during the continuous cycle of charging and discharging, causing the battery performance to degrade, ROYPOW NTC thermistors come in handy in temperature monitoring, control, and compensation for enhanced safety, performance, and reliability, ensuring efficient operation and prolonging the lifespan of the battery system.

Specifically, if the temperature exceeds the limits, it might lead to thermal runaway, causing the battery to overheat or catch fire. ROYPOW NTC thermistors provide real-time temperature monitoring, allowing the BMS to reduce the charging current or shut down the battery to prevent overheating. By measuring the temperature accurately, the NTC thermistors not only help the BMS to more precisely determine the state of charge (SOC), which is crucial for optimizing battery performance and ensuring the reliable operation of the forklift, but also enable early detection of potential issues such as battery degradation or malfunction, which reduces the maintenance frequency, cutting down the risk of unexpected failures and downtime of the forklift battery.

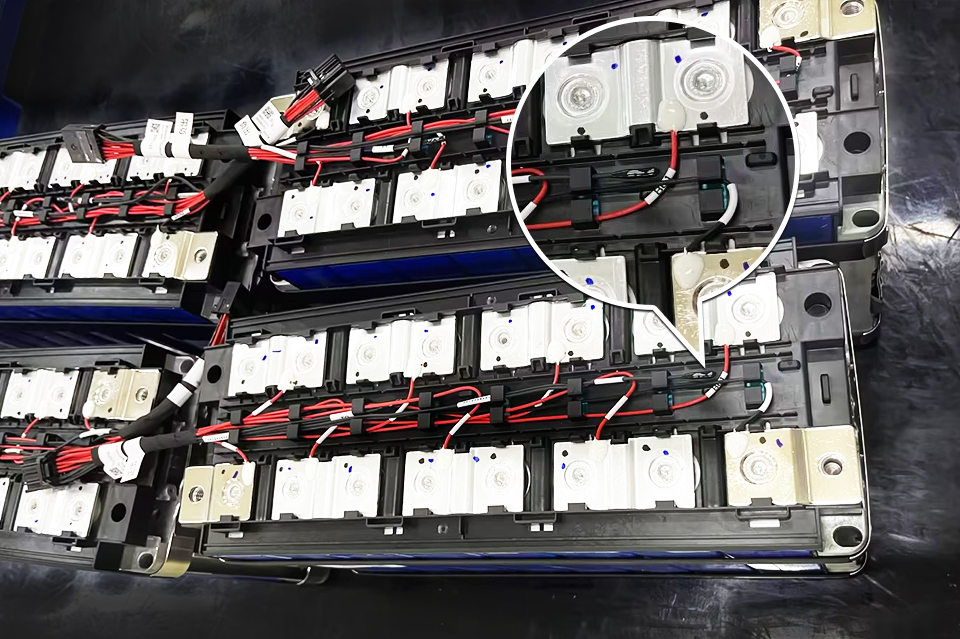

Module Manufacturing

The last essential feature that stands ROYPOW out is the advanced module manufacturing capabilities. ROYPOW has developed standard battery modules for forklift batteries of different capacities, and each module is manufactured to automotive-grade reliability. The professional R&D team provides strict control over the design of counterweight, display, external portal modules, spare parts, and more to ensure standard modules can be quickly combined with the battery systems. All contributes to efficient manufacturing, increased production capacity, and quick response to client demands. ROYPOW has partnered with the dealers of famous brands such as Clark, Toyota, Hyster-Yale, and Hyundai.

Conclusions

To conclude, the fire extinguishing system, 4G module, low-temperature heating, NTC thermistor, and module manufacturing features significantly enhance the safety and performance of ROYPOW LiFePO4 forklift batteries and in the long run, lower the total cost of ownership for businesses managing electric forklift fleets. More robust features and functions are integrated seamlessly into the batteries, adding great value and positioning ROYPOW power solutions as a game-changer in the material handling market.

Related article:

What you should know before buying one forklift battery?

Why choose RoyPow LiFePO4 batteries for material handling equipment?

Lithium ion forklift battery vs lead acid, which one is better?